Aluminum Material Timing Belt Pulley HTD3M Type

As one of the timing belt pulley manufacturers, suppliers, and exporters of mechanical products, We offer timing belt pulley and many other products.

Please get in touch with us for details.

Mail:sales@timingbeltpulley.net

Manufacturer supplier exporter of the timing belt pulley.

Aluminum Material Timing Belt Pulley HTD3M Type

One of the most popular products of the Timing Pulley factory is the P2M/P3M/P8M high torque timing pulley. This pulley is very durable and meets the highest standards of quality. It has above-average uptime, low maintenance requirements and easy operation. It comes in a variety of sizes and teeth.

These high-torque timing belts have teeth on both sides of the block to minimize the chance of skidding. These teeth also reduce the load on the bearing. High torque timing belt is available with a wide range of tooth shapes. They are offered in a variety of tones to suit a variety of applications.

Choosing the right synchronous pulley for a specific application is crucial to ensure optimal performance. Choosing a synchronization belt that is compatible with your application and engine is essential. When choosing a synchronous belt pulley, the diameter and relative center position of the belt pulley should be considered. Timing belts are usually sold by catalog length.

Timing Belt Pulley Specification:

| Product Name | Timing Belt Pulley | |

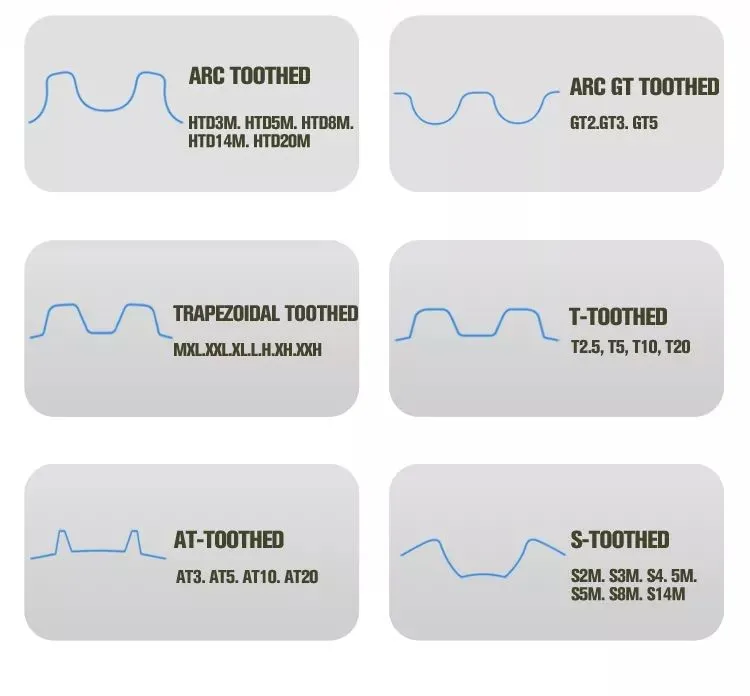

| Teeth profile | Trapezoidal toothed | MXL, XXL, XL, L, H, XH, XXH |

| T-toothed | T2.5, T5, T10, T20 | |

| Arc toothed | HTD3M, HTD5M, HTD8M, HTD14M, HTD20M, Gt2, Gt3, Gt5 | |

| S-toothed | S2M, S3M, S4.5M, S5M, S8M, S14M | |

| Parabolic-toothed | P2M, P3M, P5M, P8M, P14M | |

| Y-toothed | G2M, G3M, G5M, Y8M | |

| Teeth Quantity | 10-150 teeth or customized | |

| Inner Bore | 2-200mm H7 precision or customized | |

| Belt width | 4mm, 6mm, 9mm, 10mm, 12mm, 15mm, 20mm, 25mm, 30mm, 40mm, 50mm, 1/4”, 5/16”, 3/8”, 1/2”, 3/4”, 1”, 1.5”, 2”or customized | |

| Accessories | We can provide the service of assembling setscrews, bearings, shafts, or taper bush. | |

| Surface treatment | Anodize, Black Oxide, Phosphate, and Galvanization | |

| Drawing Format | Timing belt pulley cad drawing, timing belt pulley UG drawing, Timing belt Pulley Soilwork drawing, Timing Pulley PDF drawing | |

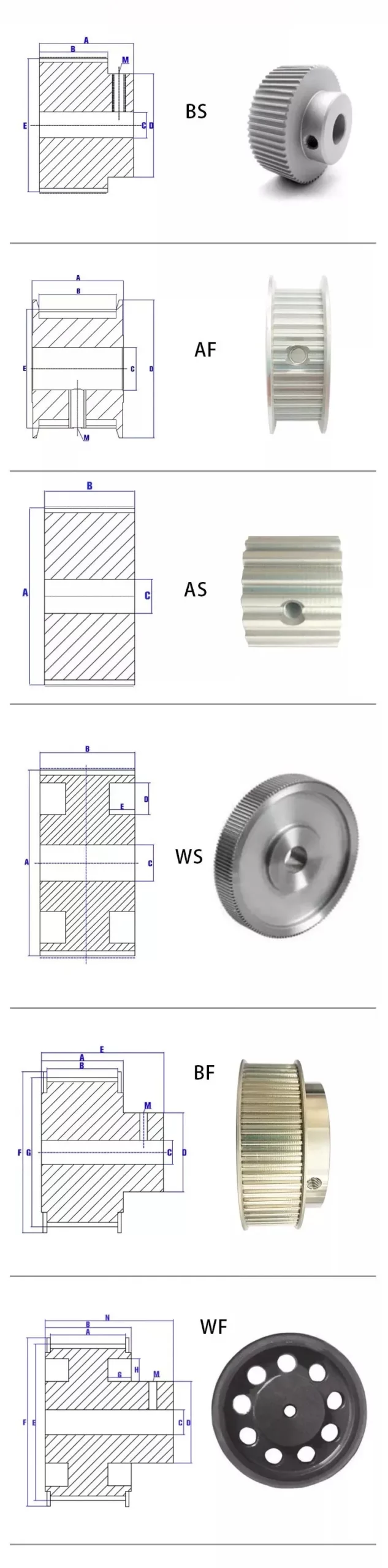

Other Timing Belt Pulley Types:

Buy the best/top china timing belt pulley. We have a bulk cheap timing belt pulley for sale at a competitive price!ANSI standard timing belt pulley and custom timing belt pulley are available! Contact now!

What Can We Do Teeth Shape?

Timing Belt Pulley VS Other Pulley:

Synchronous belt wheel is not the only variation available. Depending on your specific application, choosing another pulley may be ideal. The most common choices are multi-rib, variable speed, and V-belt pulleys.

(1) Multi-rib pulley

Multi-ribbed pulleys are found in many applications, including fans, dryers, microwave ovens, and chair lifts. Multi-ribbed pulleys are designed for higher torque in compact environments with minimal space for power.

(2) Variable speed pulley

Unlike multi-ribbed pulleys, variable speed pulleys are usually used for larger applications, such as heavy machinery. As the name suggests, variable speed pulleys are designed to change the speed of the shaft, increasing or decreasing the number of revolutions per minute as needed.

(3) v belt block

It gets its name from the tapered pulley edge that forms a V-shaped groove. The V-belt wheel is a conveyor belt that transfers power from the engine to auxiliary components, including alternators and hydraulic pumps. Because of their relatively low cost, V-belt pulleys are a popular choice.

(4) synchronous belt wheel

Due to their reliability, these pulleys are known for minimal operational problems and strictly maintained system timing. Also, unlike many pulleys, the drive belt and gear do not contact directly from surface to surface, eliminating the need for continuous lubrication. Finally, synchronous belt wheels greatly reduce operating noise, rather than chains or gears.

Quenching and Heat Treatment Process of Timing Belt Pulley:

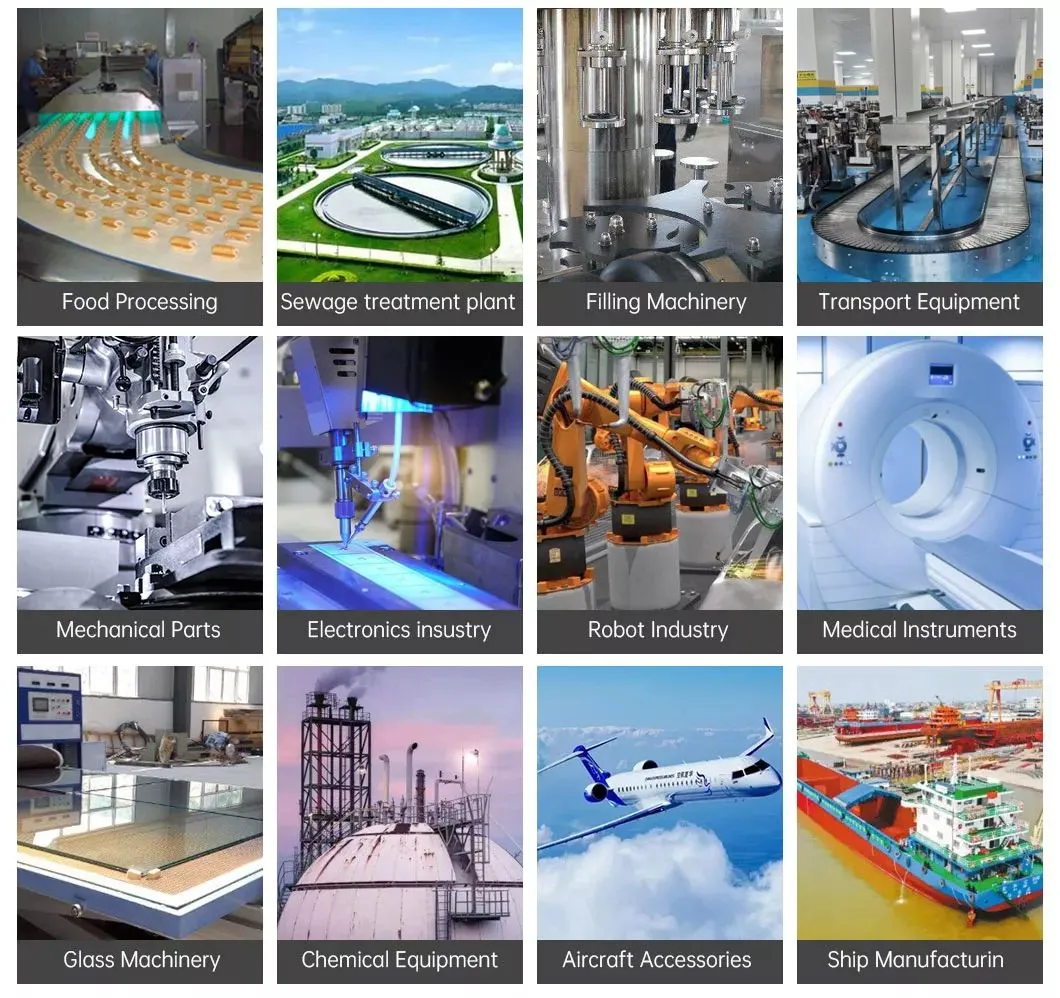

Timing Pulleys Application:

Timing pulleys are widely used in a variety of applications and manufactured using different materials, including steel, aluminum and plastic polymers. Some plastics have excellent tensile strength, chemical resistance and self-lubrication. These characteristics make them ideal for corrosion and extreme temperature applications.

The main function of the timing pulley is to align the movement of multiple gear shafts. The teeth of the pulley are crucial to this task because they ensure alignment and proper timing of the rotation. According to the power transmission requirements and alignment requirements, the pulley can be arranged in several ways.

Synchronous belt wheels are used in systems where speed is required. They can be found in a variety of applications, including engines, automation equipment, printers and other mechanical devices. The teeth on the timing belt wheel help keep the timing belt fully aligned, preventing it from slipping off the track.