Timing Belt Pulley S3M Type

As one of the timing belt pulley manufacturers, suppliers, and exporters of mechanical products, We offer timing belt pulley and many other products.

Please get in touch with us for details.

Mail:sales@timingbeltpulley.net

Manufacturer supplier exporter of the timing belt pulley.

Timing Belt Pulley S3M Type

Unlike gear or chain systems, synchronous belt pulley systems can span a wider area and require little maintenance and refueling. In addition, they can be changed more easily than gears by simply changing the pulley size and obtaining the correct size belt. Synchronous belt wheels are also significantly quieter and smoother than chain – and gear-operated synchronous systems.

Timing Belt Pulley Features:

- Preborn timing pulley design

- High-grade material Aluminum 6082

- Precise pulley dimension

- Individual packing for safety

- The existence of belt teeth and pulley tooth helps to eliminate slippage, which is also used to limit speed variation.

- The belt teeth are engaged with the axial pulley groove. This is done exceptionally smoothly and helps lower the friction to the minimum. This also helps to reduce noise or wear.

- These pulleys have high mechanical efficiencies and are available with no friction and elongation. This helps to lower the bearing load and thus helps to enhance the life of the bearing.

- The driving range lies between 10 RPM to 10000 RPM between the spindles.

- There is no need for a lubrication system due to the absence of contact between the metal. Hence there is no need for any oil-related device.

Timing Belt Pulley Parameters:

What is a Timing Belt Pulley Used For?

Pulleys are designed in a variety of ways to suit a wide variety of applications. Usually, the pulley is smooth and responsible for power transmission between the components.

The belt creates friction along the pulley wheel’s surface (usually ribbed), which causes the gear body to rotate. Traditional belts allow asynchronous, variable-speed operation. However, there is a risk of slip and time on the horizontal surface of the ribs.

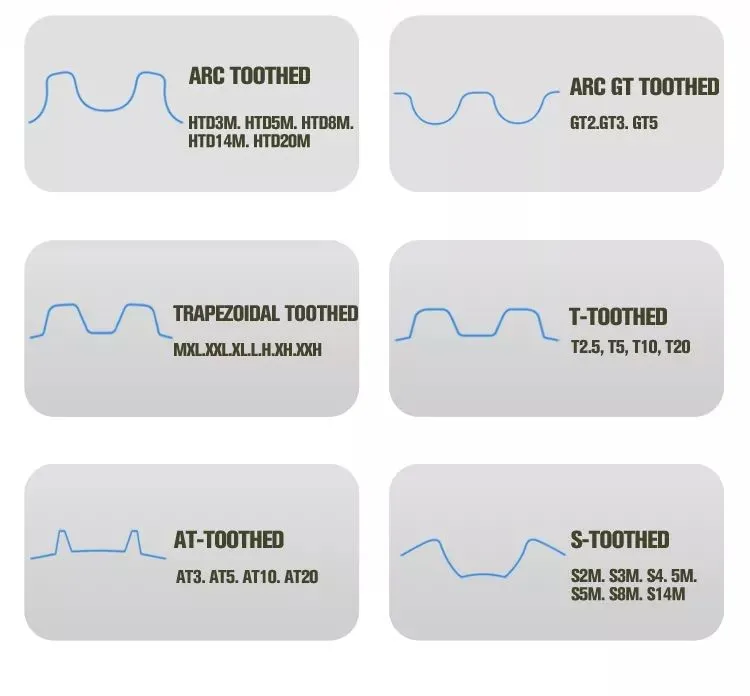

What Can We Do Teeth Shape?

Timing Belt Pulley VS Other Pulley:

Synchronous belt wheel is not the only variation available. Depending on your specific application, choosing another pulley may be ideal. The most common choices are multi-rib, variable speed, and V-belt pulleys.

(1) Multi-rib pulley

Multi-ribbed pulleys are found in many applications, including fans, dryers, microwave ovens, and chair lifts. Multi-ribbed pulleys are designed for higher torque in compact environments with minimal space for power.

(2) Variable speed pulley

Unlike multi-ribbed pulleys, variable speed pulleys are usually used for larger applications, such as heavy machinery. As the name suggests, variable speed pulleys are designed to change the speed of the shaft, increasing or decreasing the number of revolutions per minute as needed.

(3) v belt block

It gets its name from the tapered pulley edge that forms a V-shaped groove. The V-belt wheel is a conveyor belt that transfers power from the engine to auxiliary components, including alternators and hydraulic pumps. Because of their relatively low cost, V-belt pulleys are a popular choice.

(4) synchronous belt wheel

Due to their reliability, these pulleys are known for minimal operational problems and strictly maintained system timing. Also, unlike many pulleys, the drive belt and gear do not contact directly from surface to surface, eliminating the need for continuous lubrication. Finally, synchronous belt wheels greatly reduce operating noise, rather than chains or gears.

Quenching and Heat Treatment Process of Timing Belt Pulley:

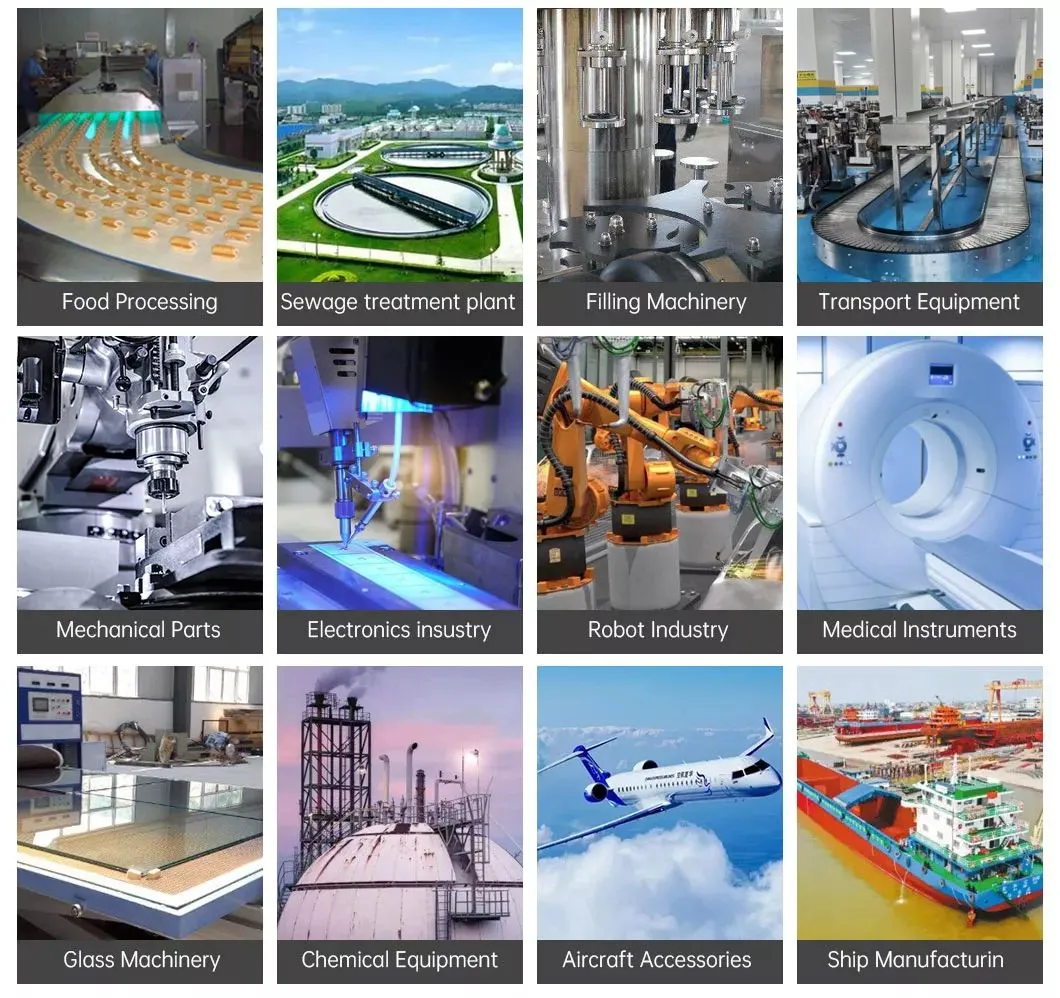

Timing Pulleys Application:

Timing pulleys are widely used in a variety of applications and manufactured using different materials, including steel, aluminum and plastic polymers. Some plastics have excellent tensile strength, chemical resistance and self-lubrication. These characteristics make them ideal for corrosion and extreme temperature applications.

The main function of the timing pulley is to align the movement of multiple gear shafts. The teeth of the pulley are crucial to this task because they ensure alignment and proper timing of the rotation. According to the power transmission requirements and alignment requirements, the pulley can be arranged in several ways.

Synchronous belt wheels are used in systems where speed is required. They can be found in a variety of applications, including engines, automation equipment, printers and other mechanical devices. The teeth on the timing belt wheel help keep the timing belt fully aligned, preventing it from slipping off the track.