Timing Belt Pulley XL Type

As one of the timing belt pulley manufacturers, suppliers, and exporters of mechanical products, We offer timing belt pulley and many other products.

Please get in touch with us for details.

Mail:sales@timingbeltpulley.net

Manufacturer supplier exporter of the timing belt pulley.

Timing Belt Pulley XL Type

The timing belt pulley comprises an annular belt with a center tooth on the inner surface and a belt pulley with corresponding teeth. It is a new type of belt drive that integrates the advantages of belt drive, chain drive, and gear drive. When running, the belt teeth engage with the tooth groove to transfer movement and power.

Timing Belt Pulley Specification:

| Product | Timing Belt Pulley & idler pulley |

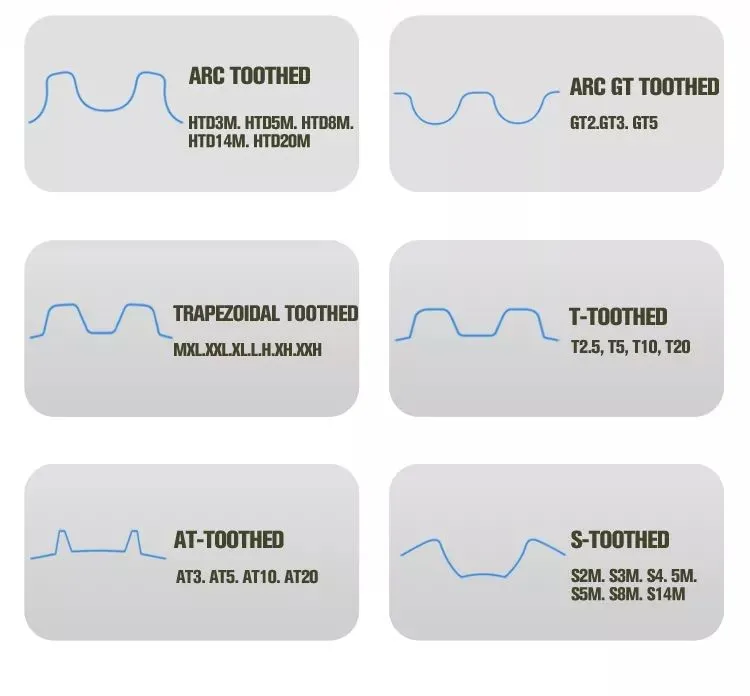

| Teeth type | Normal Torque Drive Type: MXL, XL, L, H, XH, XXH High Torque Drive Type:S2M,S3M,S5M,S8M,HTD2M,HTD3M,HTD5M,HTD8M,P2M,P3M,P5M,P8M High Precision Position Drive Type:2GT,3GT,5GT,8YU Light Load Drive Type: T5, T10, T20 Heavy Load Drive Type: AT5, AT10, AT20 |

| Basic shape | Type A,Type B,Type D,Type E,Type F,Type K |

| surface treatment | Natural color anodizing, Black anodizing, Hard anodizing, Ni-plating, Blackening |

| Material | 6061(aluminum),S45C(45# steel),SUS304(Stainless steel) |

| Bore | Pilot bore, Taper bore, and Customized bore. |

| testing equipment | projecting apparatus, salt spray test, durometer, coating thickness tester,2D projector |

| producing equipment | CNC machine, automatic lathe machine, stamping machine, CNC milling machine, rolling machine, lasering, tag grinding machine, etc. |

| Machining Process | Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding, and Gear Lapping |

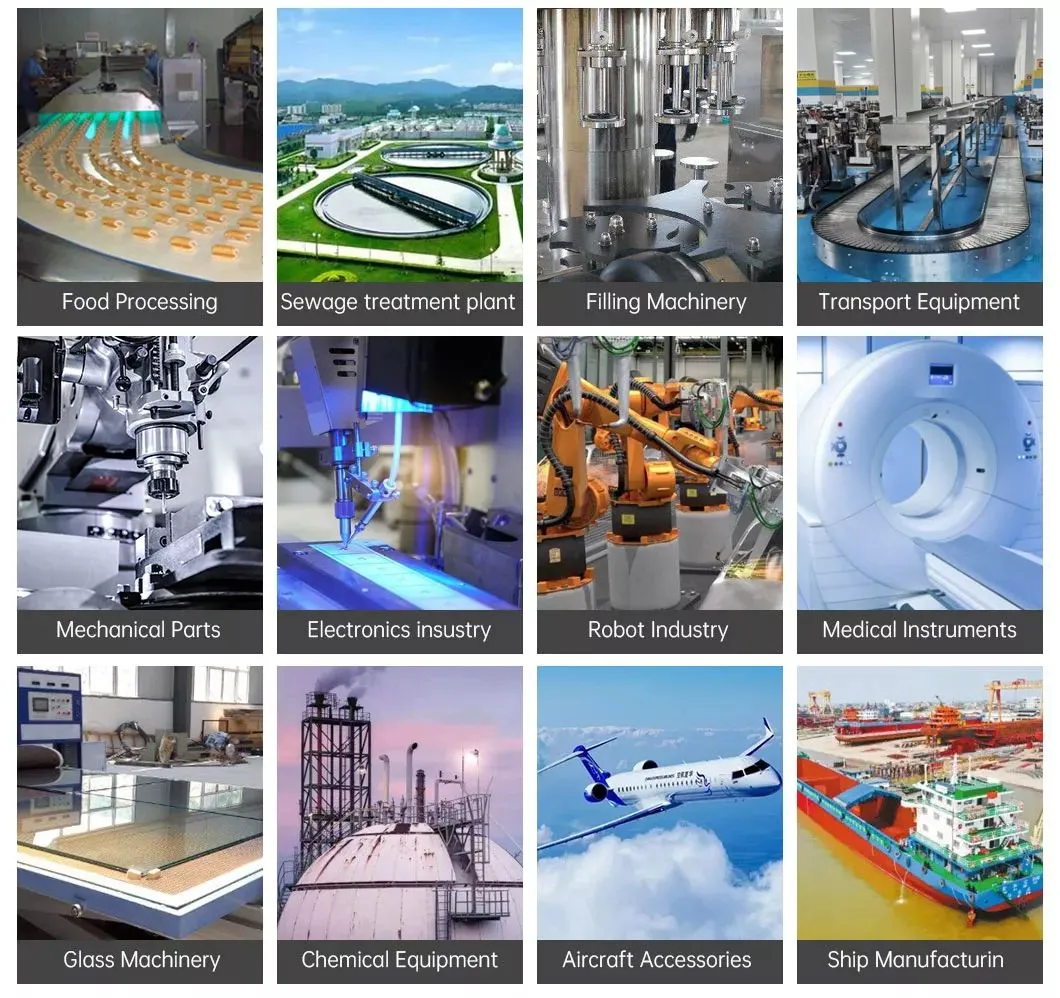

| Application industry | Robot industry, Medical industry, Making machine industry, Automation industry,3C industry equipment, Packaging industry, UAV industry, and New energy industry. |

| Advantages | 1. High-temperature resistance, Self-lubrication, Wear resistance, Flame retardant properties 2. Good quality products 3. Competitive prices 4. Fast delivery 5. Best after-sale service 6. OEM/ ODM 7. Good service: satisfactory service before and after the sale. 8. Direct manufacturers |

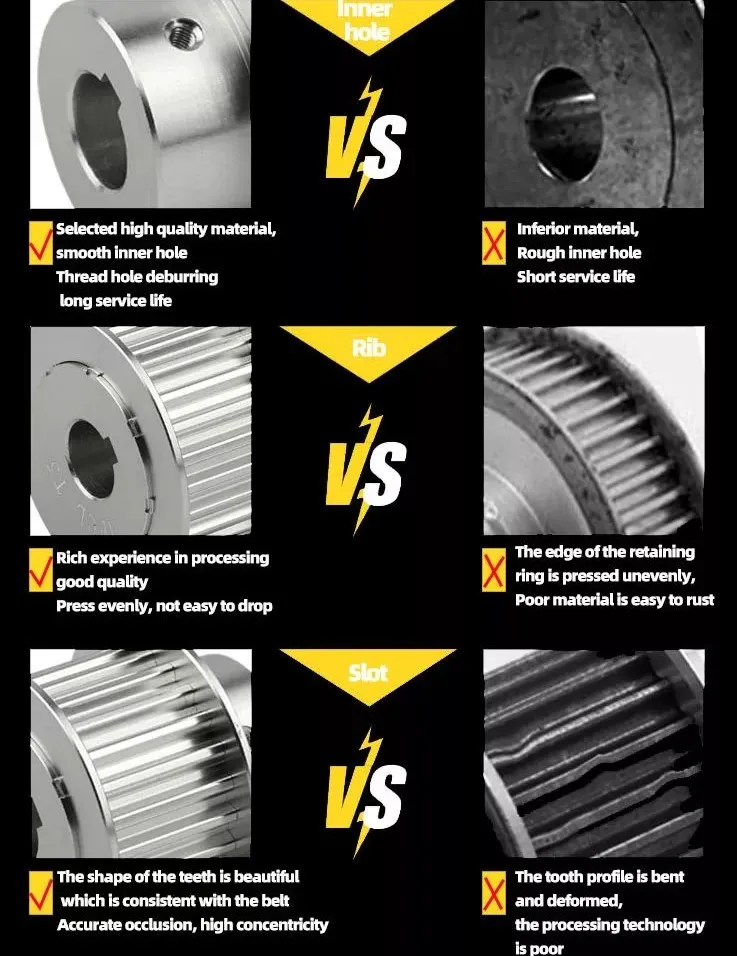

Our Timing Belt Pulley vs. Other Pulley:

How To Remove Timing Belt Pulley?

1. Remove the Radiator

2. Remove Spark Plugs

3. Remove Water Outlet

Remove the two bolts, water outlet, and thermostat with gasket.

4. Remove A/c Belt

Toyota 5mge Timing Belt Removal Tool

5. Remove The Fan And Alternator Drive Belt

6. Remove Ps Belt

Toyota Passo Fix Fan Belt Pull

7. Remove The No.3 Timing Belt Cover

Remove the five bolts, nuts, and No.3 timing belt cover with the gasket.

8. Set No.1 Cylinder To Tdc/compression

(a) Turn the crankshaft pulley and align its groove with the “0” mark on the No.1 timing belt cover.

(b) Check that the match marks on the camshaft timing pulleys and No.2 timing belt cover are aligned.

If not, turn the crankshaft pulley one complete revolution.

9. Remove Timing Belt From Camshaft Timing Pulleys

HINT: If reusing the timing belt, draw a direction arrow on the belt (in the direction of engine revolution).

(a) Loosen the idler pulley bolt and shift it left as far as it will go with a screwdriver and wrench.

(b) Temporarily tighten the set bolt and then relieve the timing belt tension. <c) Remove the belt from the camshaft timing pulleys.

HINT:

• Support the belt, so the crankshaft timing pulley and timing belt meshing do not shift.

• Be careful not to drop anything inside the timing belt cover.

• Do not allow the belt to come into contact with oil. Water and dust.

10. Remove Camshaft Timing Pulleys

Using SST to hold the pulley, remove the pulley bolt, time the pulley, and match the pin. SST 09278*54012

HINT: Place the match marks on the camshaft timing pulley where the straight pin is inserted.

NOTICE: Do not use the timing belt tension when removing and installing the pulley bolts.

Remove Corolla Crankshaft Pulley

11. Remove Crankshaft Pulley

(a) Loosen the pulley bolt using SST to hold the crankshaft pulley.

SST 09213-70010 and 09330 00021

(b) Remove SST and pulley bolt.

(c) Using SST, remove the pulley. SST 09213-31021

12. Remove Ps Air Pipe

What Can We Do Teeth Shape?

Timing Belt Pulley VS Other Pulley:

Synchronous belt wheel is not the only variation available. Depending on your specific application, choosing another pulley may be ideal. The most common choices are multi-rib, variable speed, and V-belt pulleys.

(1) Multi-rib pulley

Multi-ribbed pulleys are found in many applications, including fans, dryers, microwave ovens, and chair lifts. Multi-ribbed pulleys are designed for higher torque in compact environments with minimal space for power.

(2) Variable speed pulley

Unlike multi-ribbed pulleys, variable speed pulleys are usually used for larger applications, such as heavy machinery. As the name suggests, variable speed pulleys are designed to change the speed of the shaft, increasing or decreasing the number of revolutions per minute as needed.

(3) v belt block

It gets its name from the tapered pulley edge that forms a V-shaped groove. The V-belt wheel is a conveyor belt that transfers power from the engine to auxiliary components, including alternators and hydraulic pumps. Because of their relatively low cost, V-belt pulleys are a popular choice.

(4) synchronous belt wheel

Due to their reliability, these pulleys are known for minimal operational problems and strictly maintained system timing. Also, unlike many pulleys, the drive belt and gear do not contact directly from surface to surface, eliminating the need for continuous lubrication. Finally, synchronous belt wheels greatly reduce operating noise, rather than chains or gears.

Quenching and Heat Treatment Process of Timing Belt Pulley:

Timing Pulleys Application:

Timing pulleys are widely used in a variety of applications and manufactured using different materials, including steel, aluminum and plastic polymers. Some plastics have excellent tensile strength, chemical resistance and self-lubrication. These characteristics make them ideal for corrosion and extreme temperature applications.

The main function of the timing pulley is to align the movement of multiple gear shafts. The teeth of the pulley are crucial to this task because they ensure alignment and proper timing of the rotation. According to the power transmission requirements and alignment requirements, the pulley can be arranged in several ways.

Synchronous belt wheels are used in systems where speed is required. They can be found in a variety of applications, including engines, automation equipment, printers and other mechanical devices. The teeth on the timing belt wheel help keep the timing belt fully aligned, preventing it from slipping off the track.